Community Questions and Answers

Set out below, are a series of answers to some general questions we anticipate you may have concerning onshore oil and gas exploration, appraisal, development and production activities carried out by oil and gas companies in the UK.

Q. Where can companies explore for oil and gas in the UK?

A. Only in areas that are approved and licensed for exploration and development by the UK Department of Energy and Climate Change (DECC) and the UK Oil and Gas Authority. For further information click here.

Q. What does exploration mean?

A. It is essentially the searching process a company engages in, in order to discover the location, quality and extent of oil and gas resources. To do this, companies have access to a vast bank of readily available UK geological and geophysical (seismic) survey data. Exploration companies also use highly sophisticated technology to examine, detect and determine the presence of hydrocarbons using gravity survey, magnetic survey, passive seismic or regional seismic reflection surveys to detect features of the sub-surface geology. This exploration process is non intrusive to the local community. Explanations for some of the terms we use can be found in the Glossary elsewhere on the website.

Q. What about when a decision is made to drill an exploration well?

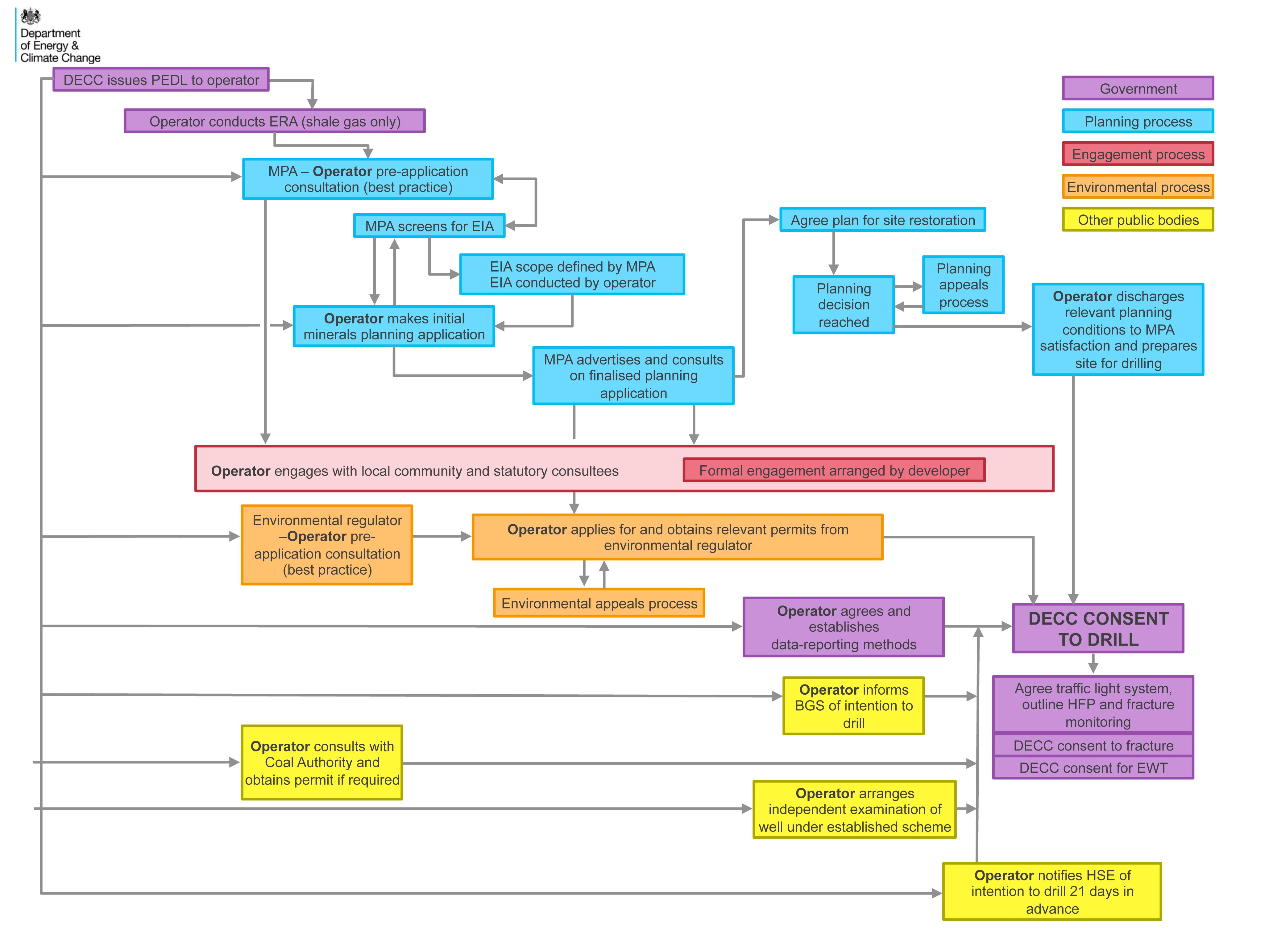

A. Drilling of exploration wells only normally takes place in locations that are not close to rural villages or houses and in locations that could not unduly disrupt the local community. In UK, there is a very long, complex and stringent regulatory, planning and environmental approval process to go through in order to be able to get to the point of drilling an exploration well. That approval process is illustrated below. The community is notified by local authority planning officers well in advance of any drilling activity. So, when the application for an exploration well has been submitted, the community has the right to voice its concerns to local authority planning officials if it feels the project will have an adverse impact. The community is consulted extensively throughout this process.

UK Government planning flow chart

Q. What happens when an exploration well has been fully approved and the drilling activity is being prepared?

A. Typically the site where the exploration well will be drilled will be fenced off in the first instance. A security company will be employed to keep the site safe. Road access will be required for a lorry to enter the site, initially with construction materials to create the small pad where the drilling rig will operate. A temporary office cabin will be installed, where the drilling rig crew and supervisory team will take up temporary residence whilst the drilling is underway. The drilling rig will be delivered to site and positioned. Before drilling commences, the well site construction will be completed so as to ensure it satisfies all company and external health and safety procedures and has necessary environmental approvals before drilling can commence.

Q. How long will this exploration drilling process take?

A. It takes, depending on the weather conditions, up to 4 weeks to prepare the site. After the drill rig arrives and depending on what depth the drill rig will reach, the drill rig can typically be on site for 4 to 8 weeks.

Q. Are there a lot of heavy goods vehicles visiting the site each day whilst this drilling rig is operating?

A. No. After the drilling rig and initial equipment have arrived, there will be much reduced road traffic. Drill rig crew, company staff and contractors will visit the site. The regulatory authorities will be checking on the process. These visitors normally arrive by car. Remember the security company will be looking after the site.

Q. Will the drilling operations contaminate the groundwater?

A. No, the wells are cased in steel and concrete to protect the integrity of the well and of the surrounding rock formations and aquifers.

Q. Will the drilling operations cause air pollution?

A. No, the drilling rig will cause negligible air pollution; oil and gas activities are highly regulated when it comes to our impact on air quality.

Q. Will the drilling rig be noisy?

A. No. The process is relatively quiet and will be at a prescribed minimum distance from any residential houses. Noise levels are regulated in the planning process and the drilling rig is generally shielded to reduce noise. So, drilling does not proceed if the regulators consider the noise level to be disruptive, or beyond prescribed limits.

Q. What happens after the drilling process finishes?

A. The drilling rig will be removed and the site will be rigorously cleaned of any residual hydrocarbons. The point where the drilling rig entered the ground will be plugged and a valve will be placed on the casing joint that was used in the drilling process to prevent any leakage or anything escaping or entering into the well. All waste and equipment will be removed. The fencing may stay in place, or may be removed, depending on the next agreed activities. Oil and gas companies then assess the results of the drilling, with the support of external consultants. Rock core samples from the drilling process are sent off for geochemical analysis. Depending on the results from the exploration process, an oil and gas company will decide whether or not to submit an application to the regulatory bodies for the exploration well to be flow tested.

Q. What is flow testing?

A. Flow testing would only proceed if an oil or gas discovery were to be made during exploration drilling. Flow testing is a process designed to broaden the knowledge and understanding of the results secured from the data logging and geochemical analysis obtained from the exploration process. Typically, a wireline formation tester is used to capture a fluid sample and measure pressure downhole at the zone of interest in the well. Small amounts of fluids from the well are flowed to the surface through a steel pipe. The flow is controlled using a choke valve and the fluids are then sent to a holding tank. The overall objective is to identify the reservoir's capacity to produce hydrocarbons, such as oil, natural gas and condensate. Data gathered during the test period includes volumetric flow rate, reservoir fluid composition and pressue/temperature observed in the selected well. The results of a well flow test, for instance discovering what the flow rate data and gas to oil ratio data is, enable the oil and gas company to determine whether the well can be a potentially commercial production well and field development can proceed.

Q. How long does the flow test take?

A. Flowing of the well under test typically lasts only a few days to a week. However, it may last longer if extended testing is approved by the regulatory authorities for complex discoveries. Remember the flow testing process is tightly regulated to make sure there is no pollution and control systems are in place whilst the flow test is being undertaken. There is very little in the way of vehicle visits to and from the site whilst flow testing is underway, although produced oil may be removed by infrequent road tankers.

Q. What happens if tests are positive and a company wants to start full-scale production?

A. The oil and gas company will have to go through another set of approvals for the well or field to enter production. Detailed development plans have to be submitted to all the regulatory bodies that govern UK onshore activities. Again, the local community will be closely consulted throughout this planning process.

Q. What will the impact of a producing oil or gas field development be on local communities?

A. Firstly, the rules and regulations governing the development of onshore oilfields in the UK are very stringent. These are primarily intended to minimize impacts on the environment and local communities. It should be noted that there has been a long history of UK onshore oil and gas activity. There are already many oil and gas fields producing onshore UK. The largest onshore oil field in Europe is located at Wytch Farm in Dorset.

Q. What will an oil or gas field look like?

A. Current and future oil fields are and will be visually unobtrusive. Landscaping and tree cover will be used. It is likely that most people passing by the locations will not realise they are there. Remember on a conventional oil field oil is typically recovered by a pump jack, otherwise known as a nodding donkey. Submerged downhole pumps are also sometimes used.

Q. Is there any noise associated with oil field pumps?

A. Again there are stringent noise restrictions placed on an oil field development. Pump jacks are not noisy when they are running and producing oil. Downhole pumps are silent at surface.

Q. What about transport impacts? Will there be huge numbers of heavy goods vehicles visiting the site to collect the oil?

A. Onshore oil production generally involves low transport impacts. One oil road tanker can typically transport around 300 barrels of oil. Oil production of around 300 barrels of oil per day would therefore only require one visit to the site per day by an oil road tanker. Oil produced in the South of England is typically transported to the Fawley Oil Refinery near Southampton. It may be possible to export the oil by pipeline, as is the case at Wytch Farm, thus removing completely the requirement for road tanker access.

Q. What about the price of my property? Will it be devalued?

A. As stated above, Europe’s largest onshore oil field is located at Wytch Farm in Dorset. It is an oil field that during its peak produced over 100,000 barrels of oil per day. Today it produces about 18,000 barrels of oil per day. The Wytch Farm oil field is located just south of Poole in Dorset, close to the picturesque market town of Wareham and nearby the exclusive residential area of Sandbanks, a location that has the fourth highest land value per acre in the world.

Another example of the lack of intrusion of onshore oil fields is the Brockham oil field near Dorking in Surrey, which has been quietly producing for 25 years with no visual or property devaluation impact.

It can be seen from visiting the Wytch Farm oil field site that modern landscaping techniques can serve to dramatically limit the visual impact of an oil field. The latest landscaping techniques can be used to limit visual pollution and work to enhance the natural beauty of the local community. No devaluation of local property is expected. Remember, it is the government and local authorities that award planning approvals for oil and gas production. Where feasible, current or former light industrial locations could be used for drilling and production sites. These tend to have fewer residential properties nearby and good existing roads and other infrastructure.

Q. Are there any benefits to the local community from oil and gas developments?

A. Yes there are. The Crown owns the UK’s oil and gas reserves and the UK Government provides companies with licences to explore and extract those resources. Typically, 50% of all profits from oil and gas production will go back to the UK Government in the form of tax. Naturally, the Government then chooses to spend that tax as it sees fit, but we like to think that the tax we can generate from harnessing Britain’s natural resources does at some point benefit the local community where we operate.

In addition, oil and gas companies pay Business Rates to every local government where they operate.

Where possible and practical, oil and gas companies prefer to recruit and contract work locally and this will generate employment opportunities. Further, local economic impact will generate a value chain: company employees and suppliers (that become economically active in the vicinity of an exploration and then producing oilfield) usually purchase local services such as petrol, food, beverages, hotel, bed and breakfast accommodation.

The oil and gas industry is an industrial sector that is responsible for the development of a range of professional careers from geology and engineering through to oil field services and a range of specialist skills. The industry works alongside universities and where UK onshore developments proceed and where activities grow, the onshore industry’s ability to provide career opportunities for young and old alike will also grow.

Q. How will the site look after all the operations?

A. The site will be returned to original condition and re-landscaped.

Summary

We hope these questions and answers have helped provide some answers to concerns you may have about oil and gas developments in your local community. If you have further questions please don’t hesitate to let us know. On UKOG’s website we have also provided details about the history of the UK oil and gas industry, some insight into the use of oil and gas and also some technical information about onshore oil recovery methods.